BCG

Pepe Rodriguez; Bitan Datta; Stefan Gstettner; Gaurav Nath; Frank Cordes; Rajesh Shetty;

Edited by Joaquim Cardoso

Key message:

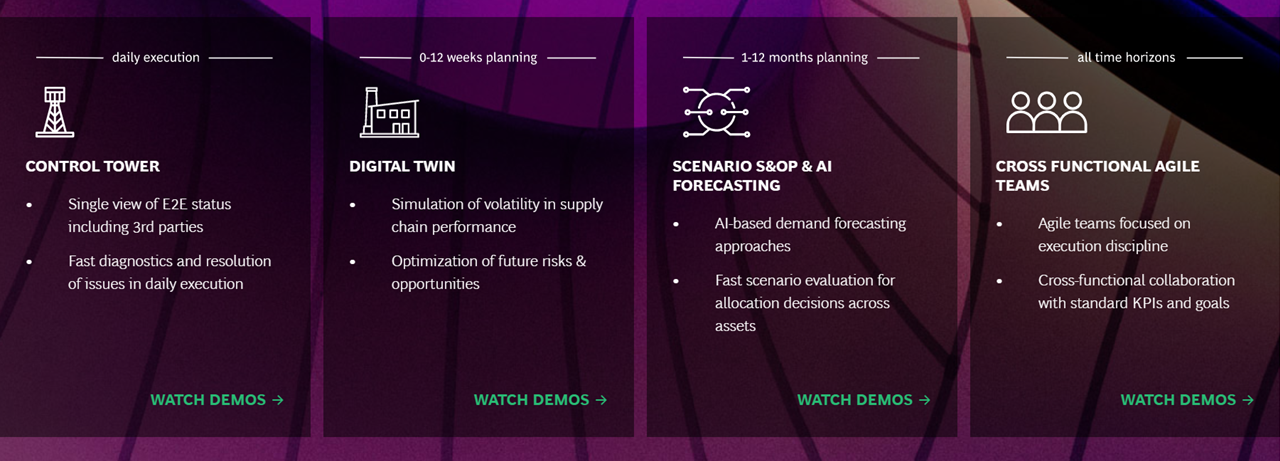

The 4 main capabilities of a Bionic Supply Chain are:

- Control Towers

- Digital Twins

- AI in Forecasting and Scenario Planning

- Cross-Functional Agile Team

Digital Supply Chain

Some business leaders think that creating a digital supply chain means automating a single task, such as forecasting demand or optimizing the production schedule.

At BCG, we know that supply chain digitization requires a holistic transformation mindset.

We know that digital solutions in supply chain management perform best — and unlock the greatest value — when they’re integrated across the entire enterprise, when they involve both processes and people.

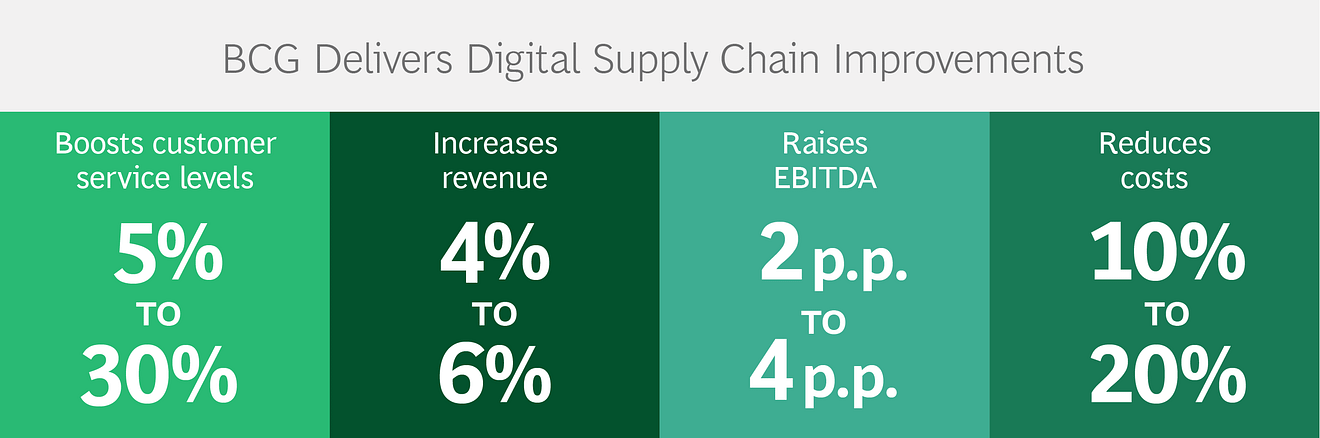

This change management approach doesn’t just position companies to be more agile, reliable, and efficient; it also delivers higher margins and lower costs.

BCG´s Bionic Approach to Supply Chain 4.0

BCG’s digital supply chain consultants develop strategies and high-tech digital solutions for our clients, leveraging our deep expertise in digital supply chains and our hands-on digital experience in Industry 4.0 and other technologies.

To maximize the value of their supply chains, leading companies adopt a bionic operating model, which intertwines the best of both man and machine — combining human know-how with the power of AI — to generate substantial improvements.

BCG’s Digital Supply Chain Capabilities

Armed with a bionic supply chain approach, leaders gain the guidance they need to capture real-time, end-to-end visibility over the supply chain.

The combination of enhanced technologies for decision making (such as big data, advanced analytics, and AI) and human creativity and collaboration enables them to deploy advanced supply chain solutions and optimize operations.

- AI in Forecasting and Scenario Planning

- Cross-Functional Agile Team

- Control Towers

- Digital Twins

1.AI in Forecasting and Scenario Planning

At BCG, our digital supply chain consultants enable our clients to achieve AI-powered planning.

We position our clients to use AI to forecast demand, plan operations, and make volume allocation decisions across assets.

These scenarios allow a company to build rigorous models — rather than relying on general guidelines — to optimize assets, such as maintenance plans and inventory buildups.

2.Cross-Functional Agile Team

When it comes to digital supply chain consulting, BCG believes that people are key enablers of any digital transformation.

So, while developing digital supply chain solutions, we enable cross-functional collaboration within our clients’ teams and work with an agile mindset.

This agility enables us to move faster, break down silos, deploy pilots and solutions quickly, and create value rapidly.

It also enables us to focus the entire team on a single goal, such as optimized customer service — and to align all employees around standardized KPIs.

3.Control Towers

As supply chains become ever more complex and critical, visibility into their real-time operations emerges as a major competitive advantage.

To manage their risks, sophisticated companies use a supply chain control tower, quickly shifting gears and priorities as conditions warrant.

We help our clients develop and deploy supply chain control tower solutions that provide a centralized view of their business’s operational status from end to end — allowing for quick diagnosis and prompt resolution of daily issues.

And because a tower sends alerts in real time, it enables maximum transparency.

4.Digital Twins

Another core solution in digital supply chain transformation is the creation of a virtual replica of a complex supply chain system: a digital twin of a company’s entire supply chain.

Using advanced analytics and AI, a digital twin simulates supply chain performance.

This model replicates all assets and interconnections, including those in production and supply, finishing and warehousing, and logistics.

As a result, it pinpoints where volatility, uncertainty, and risk exist, as well as where optimization is possible.

A digital twin can help reduce idle time by as much as 80% and delivery delays by 30%.

Clients collaborating with BCG’s supply chain digitization experts on digital twins have realized, for example,

- a 5% reduction in sustainable inventory,

- a 10% reduction in capital expenditures, and

- EBITDA growth of 1 to 3 percentage points.

BCG´s Bionic Approach to Supply Chain 4.0

BCG’s digital supply chain consultants develop strategies and high-tech digital solutions for our clients, leveraging our deep expertise in digital supply chains and our hands-on digital experience in Industry 4.0 and other technologies.

To maximize the value of their supply chains, leading companies adopt a bionic operating model, which intertwines the best of both man and machine — combining human know-how with the power of AI — to generate substantial improvements.

Meet Our Digital Supply Chain Consulting Leaders

Pepe Rodriguez; Managing Director & Partner; New Jersey

Bitan Datta; Managing Director & Partner; New Delhi

Stefan Gstettner; Partner & Director; Frankfurt

Gaurav Nath; Managing Director & Partner; London

Frank Cordes; Managing Director & Senior Partner; London

Rajesh Shetty; Partner & Associate Director; Dallas

Originally published at https://www.bcg.com.