BCG — Boston Consulting Group

by Gideon Walter, Pepe Rodriguez and Stefan Gstettner

March 26, 2019

My colleague Gideon Walter and I spoke to many supply chain executives on why supply chain control towers fail, in this article we summarize what we found

- It’s much more than another software project

- Critical to have clear value articulation, understand and manage that ways of working change, organizational impact, and change management needs

Supply chain control towers are without a doubt the dominant concept for steering the supply chains of the future.

By control tower, we mean a comprehensive concept of end-to-end connectivity, real-time visibility, predictive alerting, and multiple advanced planning approaches including associated data platforms and user interfaces.

By control tower, we mean a comprehensive concept of end-to-end connectivity, real-time visibility, predictive alerting, and multiple advanced planning approaches.

While the concept of having perfect control-and, more importantly, maximum value creation-in the supply chain is enticing, it is rarely successfully implemented.

My colleague Gideon Walter and I spoke with many supply chain executives in the United States and Europe across industries to find common factors making these efforts fail.

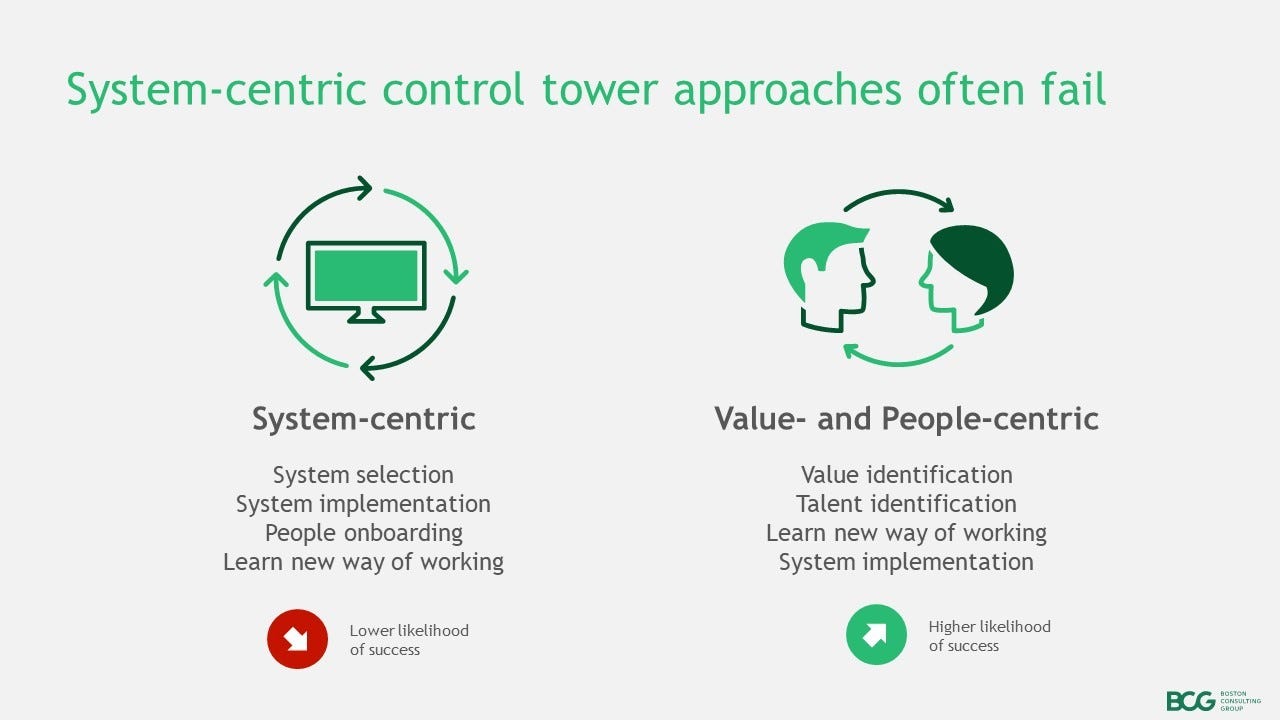

Overall, a misconception around the control tower implementation approach is the main reason for failure. We have summarized this in the picture below.

This can be broken down into four more specific reasons detailed below.

- The control tower’s value contribution was often not articulated clearly enough.

- The control tower often seems to be just another software project.

- Many organizations underestimate the massive implications a control tower has on their entire setup.

- The executives we spoke admit to us that they have not established tangible enough change efforts alongside the control tower implementation.

- The first reason we heard from the supply chain executives was that the control tower’s value contribution was often not articulated clearly enough.

They saw all the fancy new features and opportunities, but it was not obvious to them how they would help the supply chain generate superior value over the “traditional” way of working.

- Second, and we heard quite a bit of frustration about this, the control tower often seems to be just another software project.

Since another control tower software provider comes knocking at the executive’s door every month, many people in their organizations think that the software will do the trick.

On the other hand, many other monolithic software implementations have already failed in the past and executives are looking for more agile ways in order to avoid the same painful implementation journey again.

For example, one of our clients was fascinated by the concept of digital twin as a way to not only have visibility, but also simulate supply chain performance.

Several forays into the space resulted in unrealized promises.

- A visibility solution to manage material flow deteriorated into a KPI dashboarding effort.

- A predictive supply chain initiative deteriorated into a secondary planning tool.

- Not only the vision of the digital twin and simulation wasn’t realized, the client ended with additional software tools to maintain, more handoffs between tools, and even more challenges in achieving a single source of truth.

While these first two points were fairly obvious and clearly articulated by our clients in our conversations, the next two were mentioned more implicitly.

However, in the course of our talks they repeatedly emerged as the true and fundamental reasons for the limited success of the control tower efforts.

- Many organizations underestimate the massive implications a control tower has on their entire setup.

Steering a supply chain with a control tower touches on many dimensions:

- The organization,

- the ways of working in terms of processes, required capabilities, alignment of KPIs and incentives,

- and collaboration across functions and with external partners, to name only the most important ones.

Underestimating this impact turns out to be the number one reason for not making a control tower a success.

- The fourth reason is basically a consequence of the third.

The executives we spoke admit to us that they have not established tangible enough change efforts alongside the control tower implementation.

The difficulty of change management is that it is not easy to make it really tangible. Some supply chain professionals struggle to formalize what is really needed with respect to change management.

Some supply chain professionals struggle to formalize what is really needed with respect to change management.

This is what supply chain executives report on the challenging side of control tower implementations.

However, we will of course not leave you with only a statement of the problems.

In our next post, “A recipe for Supply Chain Control Tower success” my colleague Pepe Rodriguez and I will talk about our insights from successful control tower projects.