This is an excerpt of the report “The Future of Supply Chain Management 2021–2025: Balancing Sustainability, Resilience and Cost”, focusing on the topic above. For the Executive Summary of the report, please, refer to the second part of this post.

CAPS Research, BCG

Bryan Fuller, Geoff Zwemke, Daniel Weise, Alex Dolya, Chitt Jha

May 2022

Upgrading Supply Chain Technology

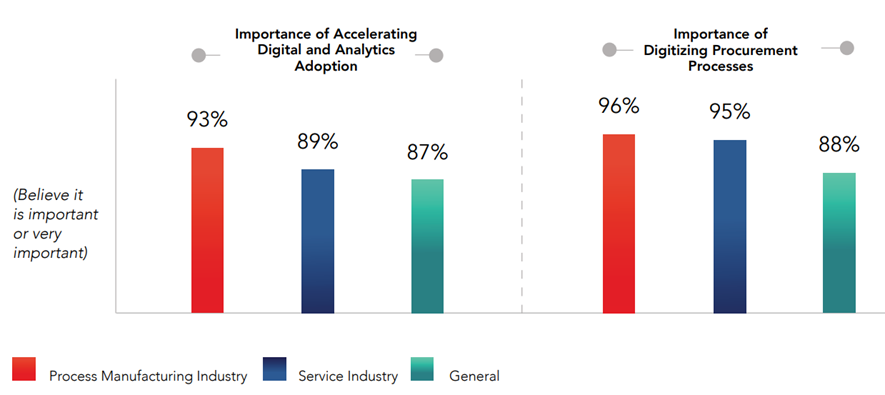

Supply chain executives believe adopting digital processes and analytics are critical initiatives going forward.

While the vast majority of respondents are eager to embrace new technologies that enable them to share information more easily and become more transparent and efficient, the survey found that process manufacturers and service companies have a more technology-forward bent than discrete manufacturers.

For example, when asked about transforming to a future-ready operating model, 83% of process manufacturing executives and 80% of service executives said doing so is extremely important, compared with 78% of overall respondents.

While the vast majority of respondents are eager to embrace new technologies that enable them to share information more easily and become more transparent and efficient …

Executives are also keen to increase the use of analytics, which will help them discover trends and make predictions about their own operations and those of their partners — information they can use to improve efficiency and eliminate bottlenecks.

Executives are also keen to increase the use of analytics, which will help them discover trends and make predictions about their own operations and those of their partners — information they can use to improve efficiency and eliminate bottlenecks.

Accelerating digital and analytics adoption was listed as a high priority by 93% of process manufacturers, 89% of service companies, and 87% of overall respondents.

Service companies and process manufacturers placed an even higher value on digitizing the procurement process, with over 95% saying it’s extremely important to do so (Figure 8).

Accelerating digital and analytics adoption was listed as a high priority …Service companies and process manufacturers placed an even higher value on digitizing the procurement process …

Figure 8: The drive to adopt analytics and digital processes

Respondents across the board emphasized the importance of better information sharing, …

with 78% overall and 80% of process manufacturing executives citing the importance of creating a common, organization-wide database for supply information.

Sharing market intelligence across business units also got high marks.

Respondents across the board emphasized the importance of better information sharing, … executives citing the importance of creating a common, organization-wide database for supply information.

Sharing market intelligence across business units also got high marks.

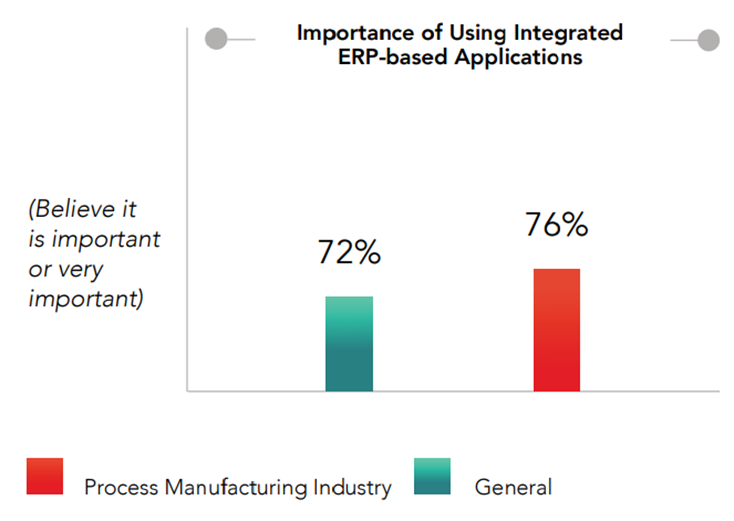

In addition, executives expressed a strong interest in better integrating their technology.

That was especially true for process manufacturers — nearly three-fourths said they believe it’s extremely important to use integrated ERP-based applications for supply management. Seventy-two percent of all respondents agreed (Figure 9).

In addition, executives expressed a strong interest in better integrating their technology.

… saying it’s extremely important to use integrated ERP-based applications for supply management

Figure 9: The use of ERP-based applications for supply management

Increased virtual and digital management of suppliers

Eighty percent of service companies, which have widely adopted digital technology to increase efficiency in recent years, are strongly in favor of increased virtual and digital management of suppliers, and nearly three-quarters of overall respondents agree.

Transfer IT services to the cloud

Service companies are also more likely to transfer IT services to the cloud, where many are already reaping the benefits of digital applications.

Acquiring new technologies as long as they supply clear economic value.

Companies are also interested in acquiring new technologies as long as they supply clear economic value. Over 80% cited developing new value-added technology as an extremely important goal.

Main technology interests are: (1) Increased virtual and digital management of suppliers; (2) Transfer IT services to the cloud; and (3) Acquiring new technologies as long as they supply clear economic value.

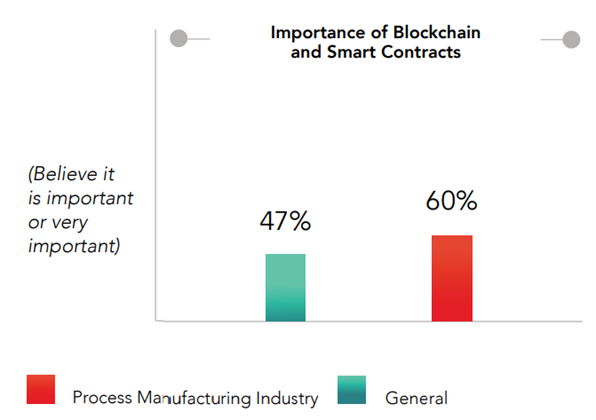

Cutting-edge technologies like blockchain could be an interesting development to watch for.

More than half of respondents — especially in the service industry — are intrigued by the prospect of managing unalterable, smart contracts on the blockchain (Figure 10).

Figure 10: The importance of blockchain and smart contracts

While it may take some time to gain widespread adoption, a blockchain initiative fits nicely with the existing high-priority goal, cited by 84% of respondents, of building transparency throughout the supply chain.

EXECUTIVE SUMMARY

The Future of Supply Chain Management 2021–2025: Balancing Sustainability, Resilience and Cost [Executive Summary]

CAPS Research, BCG

Bryan Fuller, Geoff Zwemke, Daniel Weise, Alex Dolya, Chitt Jha

May 2022

The Future of Supply Chain Management

Every five years, the Center for Advanced Procurement Strategy (CAPS), a joint initiative of the Institute for Supply Management (ISM) and Arizona State University, conducts a global survey of practicing supply chain executives and knowledge experts, asking about the challenges they expect to face and their strategies and performance goals in the coming years.

For the 2021 survey, CAPS worked with BCG to query 157 supply management leaders across industry segments, including discrete manufacturing, process manufacturing, and service industries.

We gained their insights on a host of important topics, including:

- Supply chain market dynamics

- Cost savings and efficiency

- Risk and resilience

- Environmental, social, and governance (ESG) regulations and initiatives

- Supplier management

- Supply chain operations

- Human resources

- Technology

Key Insights from Procurement and Supply Chain Leaders

Two trends in the new survey stand out.

First, fulfilling environmental, social, and corporate governance (ESG) goals has assumed paramount importance.

The second notable trend is a greater emphasis on achieving resilience in the face of unpredictable raw materials shortages and logistical challenges, which were greatly exacerbated by the pandemic.

Two trends in the new survey stand out: (1) fulfilling environmental, social, and corporate governance (ESG) goals ; (2) … a greater emphasis on achieving resilience

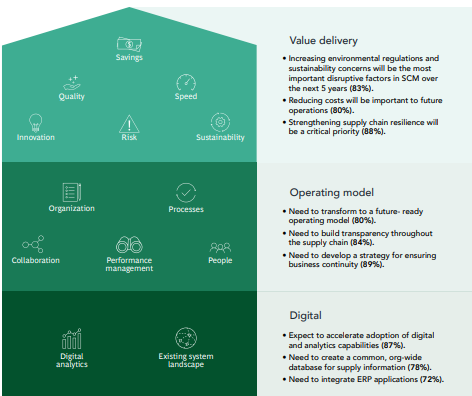

The schematic below summarizes some of the survey’s most important findings.

Summary Figure: Highlights from the 2021–2025 CAPS and BCG global survey of procurement leaders

ZOOM VIEW

Value delivery

- Increasing environmental regulations and sustainability concerns will be the most important disruptive factors in SCM over the next 5 years (83%).

- Reducing costs will be important to future operations (80%).

- Strengthening supply chain resilience will be a critical priority (88%).

Operating model

- Need to transform to a future- ready operating model (80%).

- Need to build transparency throughout the supply chain (84%).

- Need to develop a strategy for ensuring business continuity (89%).

Digital

- Expect to accelerate adoption of digital and analytics capabilities (87%).

- Need to create a common, org-wide database for supply information (78%).

- Need to integrate ERP applications (72%).

“Going forward, CPOs will need to constantly balance tradeoffs between sustainability, resilience and cost.

CPO KPIs and capabilities will need to evolve respectively to reflect all these priorities. This will be the most challenging task for the next five years,” — Alex Dolya

CPOs need also to rethink through their approach to suppliers, given their need to balance priorities.

If in the past, cost savings were primary objective of supplier engagement, today CPOs need to ensure that suppliers can deliver in the face of decarbonization, supply resilience and cost competitiveness.

Getting the equation right could prove tricky.

CPOs need also to rethink through their approach to suppliers, given their need to balance priorities. Getting the equation right could prove tricky.

Structure of the report

· The Future of Supply Chain Management

· Key Insights from Procurement and Supply Chain Leaders

· The Rising Importance of Sustainability

· The Need to Improve Supply Chain Resilience

· Sustainability and Resilience Top Cost Concerns

· 2021 vs. 2016: Different Change Drivers, Different Strategies

· Upgrading Supply Chain Technology

· Looking Forward

Report Authors

Bryan Fuller

Senior Director, Procurement, Solidigm, Former Executive Director, CAPS Research

Geoff Zwemke

Director of Product, CAPS Research

Daniel Weise

Managing Director and Partner, BCG, Global Leader for BCG Procurement Practice, CEO of Inverto

Alex Dolya

Managing Director and Partner, BCG, Asia Pacific Leader for BCG Procurement Practice, Global Leader for Procurement and SCM in Energy and Mining, BCG

Chitt Jha

Partner and Associate Director, BCG, BCG Global Expert on Procurement Resilience, Sustainability, and Digital

Originally published at CAPS Research.