What CSCOs need to know for effective supply chain transformation

Gartner, May 2021

Gartner research reveals that 38% of supply chain leaders are concerned that their supply chains are not well-positioned to handle the challenges of the next two years. Are you prepared?

Gartner surveys of hundreds of supply chain leaders reveal that chief supply chain officers (CSCOs) will need to navigate five major shifts over the next five years.

The CSCO’s imperative will be to meet purpose-driven goals whereby product sourcing, manufacturing and delivery processes serve a higher purpose and maintain economic viability.

This guide outlines those new realities, along with specific actions that CSCOs can take to reshape how supply chains organize and operate to prepare for future demands.

The COVID-19 crisis has been a catalyst for supply chain transformation, but radical change still lies ahead.

Gartner surveys of hundreds of supply chain leaders reveal that chief supply chain officers (CSCOs) will need to navigate five major shifts over the next five years.

The CSCO’s imperative will be to meet purpose-driven goals whereby product sourcing, manufacturing and delivery processes serve a higher purpose and maintain economic viability.

This guide outlines those new realities, along with specific actions that CSCOs can take to reshape how supply chains organize and operate to prepare for future demands.

The 5 Changes for Supply Chain Leaders to Act On Now are:

- Supply chain digitalization (Digital Supply Chain)

- Globalization and offshoring

- New business models

- e-commerce shift

- Remote and distributed teams

1.Supply chain digitalization (Digital Supply Chain)

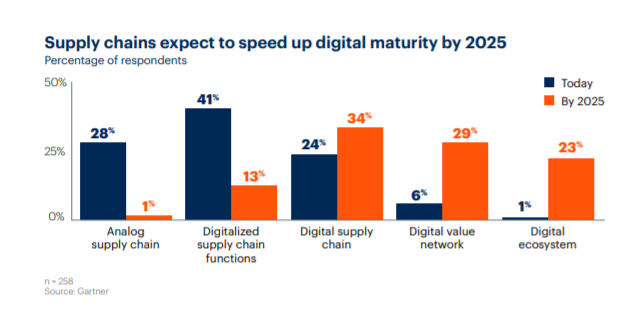

- 34% of supply chain leaders expect to have a digital supply chain by 2025, up from only 24 % today.

- 29% of supply chain leaders expect to have a digital value network by 2025, up from only 6% today.

- 23% of supply chain leaders expect to have a digital ecosystem by 2025, up from only 1% today.

What’s happening?

- As recovery from the pandemic continues, CEOs see digitalization as key to shaping business opportunity in the decade ahead.

What supply chain leaders can do?

- Take a proactive approach to supply chain digitalization.

- Develop supply chain capabilities to deliver on business priorities.

- Build a compelling business case for supply chain digital transformation.

Future of supply chain:

- Increased digitalization will result in a more resilient and agile supply chain, powered by technologies such as the Internet of Things (IoT), digital twins and blockchain.

- These technologies will digitally interconnect the supply chain ecosystem and improve network collaboration, visibility and risk management.

- Ecosystems that share end-to-end information in real time will enable supply chain organizations to support better and faster responses to unexpected changes in supply or demand.

2.Globalization and offshoring

- 46% and 61% of supply chain leaders anticipate declines in globalization and offshore manufacturing, respectively, over the next five years.

What’s happening?

- Globalization is under pressure.

- Complex and elongated supply chains, with goods sourced far away from the markets that they serve, increase working capital and lead time.

What supply chain leaders can do:

- Reassess the offshoring strategy and network.

- Reshoring needs to be balanced against cost, skills, tax implications and local market resources.

- Strike a balance between globalized, regionalized and localized supply chains.

Future of supply chain:

- A diversification of the manufacturing footprint for improved resilience and agility was already underway before 2020.

- Almost half of supply chains will move production to different countries or regions.

- Companies will invest in localized sourcing for resilience, agility and sustained growth in local markets — for example, by training local small businesses to manufacture for global supply chains.

3. New business models

- 79% of supply chain leaders think that an internet-/platform-based approach is the most critical new business model to support post pandemic recovery

What’s happening?

- New business models are taking shape to support much needed growth in a period of economic slowdown.

What supply chain leaders can do?

- Revisit and align the supply chain strategy with the new business models.

- Factor in customer segmentation, cost to serve and supply chain strategy

Future of supply chain:

- CEOs will take the opportunity to “reset” or rebuild their business for new realities.

- Supply chains will develop operational capabilities to deliver each of the outcomes associated with different value propositions.

For example, one outcome could be the customized bundling of products and services that requires more flexible processes and options for fulfilling orders. Operationally, this outcome might require different production and distribution equipment, facility designs and crew scheduling practices.

4. e-commerce shift

- 69% of supply chain organizations expect a decrease in consumer willingness to visit stores over the next five years

What’s happening?

- Government lockdowns and concern about contracting COVID-19 have led to reduced consumer traffic in stores.

- Spending has shifted online, hurting organizations that have not integrated online and physical channels.

What supply chain leaders can do?

- Build scalable capacity, including servicing online orders and returns.

- Reexamine network design to enable a more profitable operating model that supports the shift in volume toward e-commerce.

Future of supply chain:

- Supply chain will become a resilient and agile organization that can improve the customer experience (CX) by delivering on the extremes of customer preferences.

This includes, for example, personalized, purpose-driven products and services delivered anywhere, at any time and in any supply condition. - Investments will balance cost reduction with improved CX.

- In the postpandemic world, supply chains will collaborate with brands and product/ package development teams to develop sustainable, channel appropriate solutions.

5.Remote and distributed teams

- 98% of supply chain leaders believe working from home will increase over the next five years.

What’s happening?

- Culturally, supply chain organizations were always site- or office-based. This is no longer the case.

- Most employees work remotely at least part of the time.

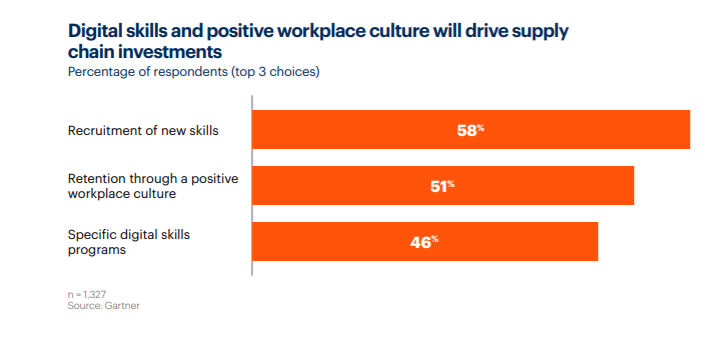

What supply chain leaders can do?

- Demonstrate empathy and flexibility.

- Support a hybrid workforce and take steps to improve the productivity of distributed teams.

Future of supply chain:

- Supply chain organizations will have a hybrid (on-site and remote) workforce permanently in place.

- The increase in remote work will provide access to a much wider talent pool.

- Productivity tracking technologies will be in widespread use.

- So will practices like virtual time logging and monitoring computer usage.

- Physical plants, warehouses and corporate offices will continue to exist but will increasingly morph into spaces for collaboration and innovation

Looking ahead: Purpose-driven supply chains

The supply chains of tomorrow will mirror the greater purpose of their top leadership.

- Purpose is not only linked to what is made, how it is made and who it serves — it’s also part of the identity of the organization and the supply chain.

Our research shows that supply chains are becoming increasingly purpose-driven.

- Purpose isn’t just about “going green.”

- Purpose-driven supply chains take proactive steps to regenerate lost natural capital by identifying relevant material issues, putting targets in place, taking action and influencing others to do the same.

They recognize that the organization’s purpose cannot be fulfilled unless the context in which business takes place is stable and improved.

- This means taking positive steps to enhance environmental and community welfare.

The pandemic highlighted the importance of supplier relationship management and being a customer of choice.

- Purpose-driven supply chains move beyond transactional relationships, focusing on innovation and collaboration.

Being profitable is no longer enough.

- Organizations led through supply chains need to demonstrate purpose by showing how their actions benefit stakeholders.

- Forward-looking supply chains will integrate this concept into how business is done

Adapted from report originally published at https://www.gartner.com